Document

I18IP001EN-A_Micro_Rotary_Riffler_Brochure

Contenu du document

RIFFLER

rotary powder sample splitters

Quantachrome

Quantachrome

Rotary Micro Riffler

Corporate Headquarters-USA

Quantachrome Instruments

a brand of Anton s?8vPaar

1900 Corporate Drive

Boynton Beach, FL 33426

© 2018 Quantachrome Corporation I18IP001EN-A Trademarks and registered trade mark are the

property of their respective owners.Serving Porous

Materials and Powder

Characterization Needs

Since 1968

Introduction

Physical measurements, such as particle size,

surface area, density, etc. and chemical analy

-

sis of crushed ores for example often require

reduction of large quantities into smaller

samples. Therefore it is necessary that the

powder sub-sample used for analysis be

representative of the initial lot or batch for

reproducible and valid data.

Both of Quantachrome's rifflers are designed

to accurately and reproducibly prepare such

representative powder samples from larger

laboratory or bulk quantities using the statisti-

cally superior method of spin, or rotary, riffling.

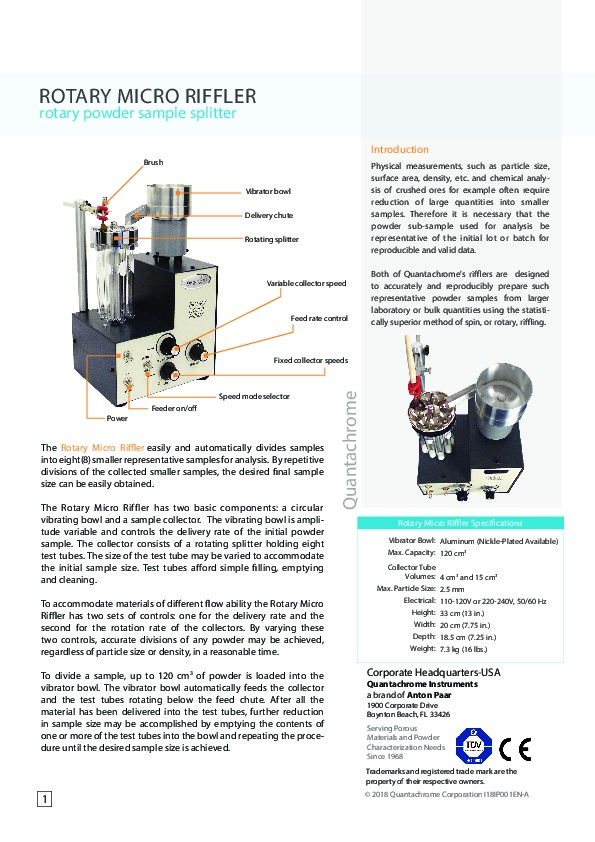

The Rotary Micro Riffler easily and automatically divides samples

into eight(8) smaller representative samples for analysis. By repetitive

divisions of the collected smaller samples, the desired final sample

size can be easily obtained.

The Rotary Micro Riffler has two basic components: a circular

vibrating bowl and a sample collector. The vibrating bowl is ampli-

tude variable and controls the delivery rate of the initial powder

sample. The collector consists of a rotating splitter holding eight

test tubes. The size of the test tube may be varied to accommodate

the initial sample size. Test tubes afford simple filling, emptying

and cleaning.

To accommodate materials of different flow ability the Rotary Micro

Riffler has two sets of controls: one for the delivery rate and the

second for the rotation rate of the collectors. By varying these

two controls, accurate divisions of any powder may be achieved,

regardless of particle size or density, in a reasonable time.

To divide a sample, up to 120 cm

3 of powder is loaded into the

vibrator bowl. The vibrator bowl automatically feeds the collector

and the test tubes rotating below the feed chute. After all the

material has been delivered into the test tubes, further reduction

in sample size may be accomplished by emptying the contents of

one or more of the test tubes into the bowl and repeating the proce -

dure until the desired sample size is achieved.

ROTARY MICRO RIFFLER

rotary powder sample splitter

Rotary Micro Riffler Specifications

Vibrator Bowl:

Max. Capacity:

Collector Tube

Volumes:

Max. Particle Size: Electrical:Height:Width:

Depth:

Weight: Aluminum (Nickle-Plated Available)

120 cm 3

4 cm 3 and 15 cm 3

2.5 mm

110-120V or 220-240V, 50/60 Hz

33 cm (13 in.)

20 cm (7.75 in.)

18.5 cm (7.25 in.)

7.3 kg (16 lbs.)

1

Power

Feeder on/off Variable collector speed

Speed mode selector Fixed collector speedsFeed rate control

Rotating splitter

Vibrator bowl

Delivery chute

Brush

Quantachrome

Entreprises concernées :

Produits concernés :

Date d'upload du document :

mardi 5 janvier 2021